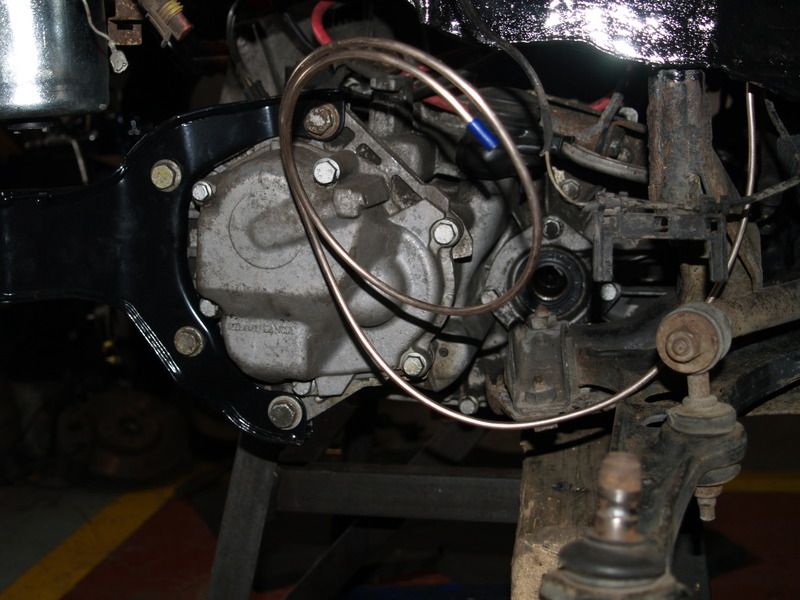

After some persuasion ("You should have told us within ten days") the supplier delivered a replacement clutch release bearing, and with a new input shaft seal, Joe's got the gearbox finally on the engine.

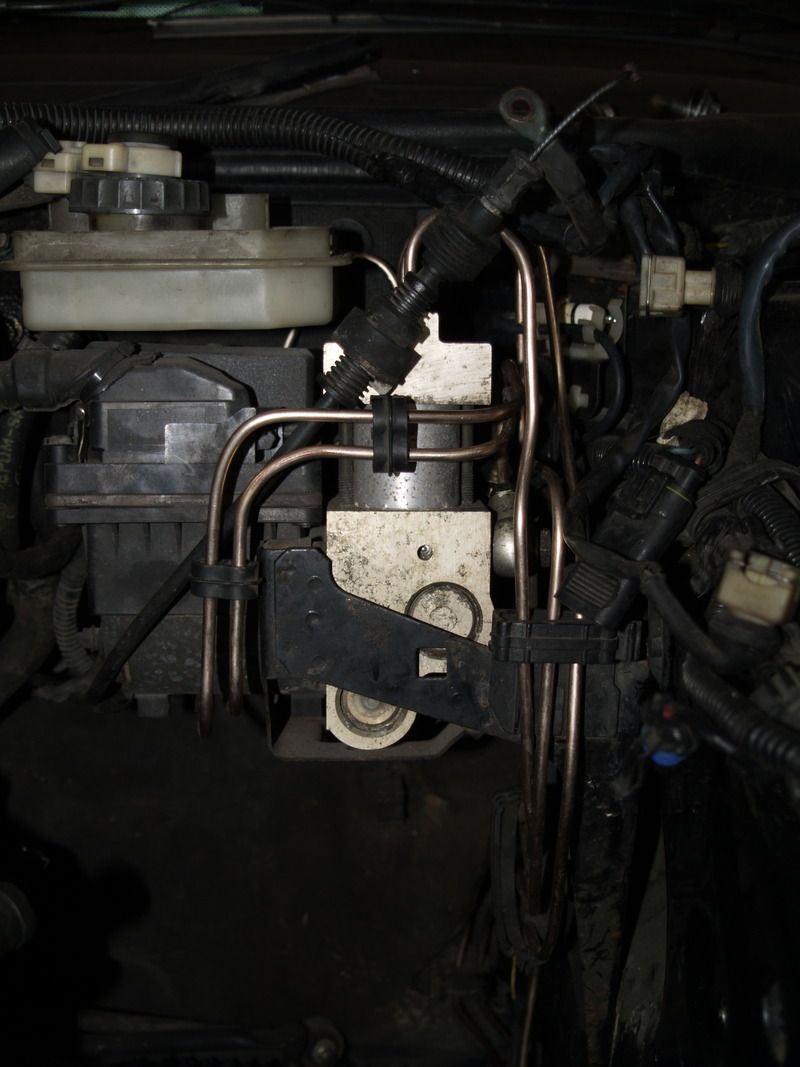

He's also been busy replacing the brake lines with shiny new cupro-nickel lines:

Then the engine and box goes back in the bay:

The bolts holding the subframe up were a little thinner than they should have been, so were replaced:

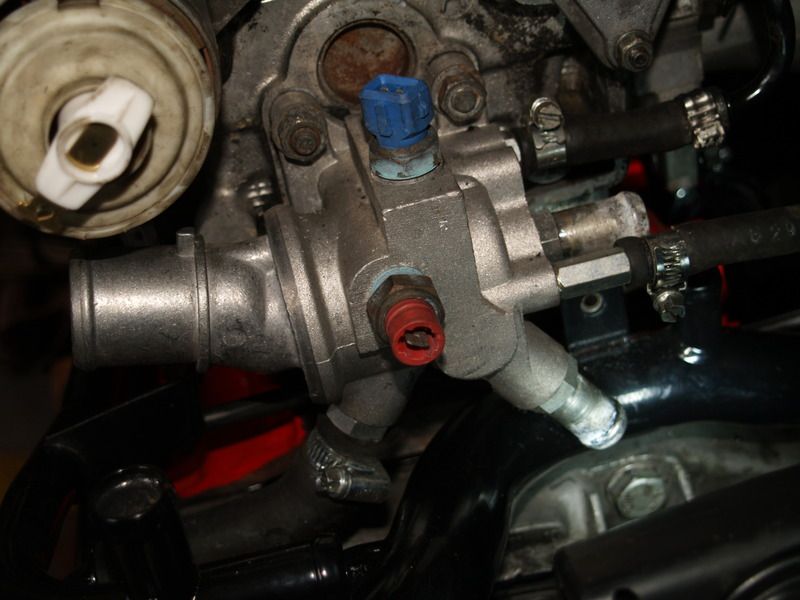

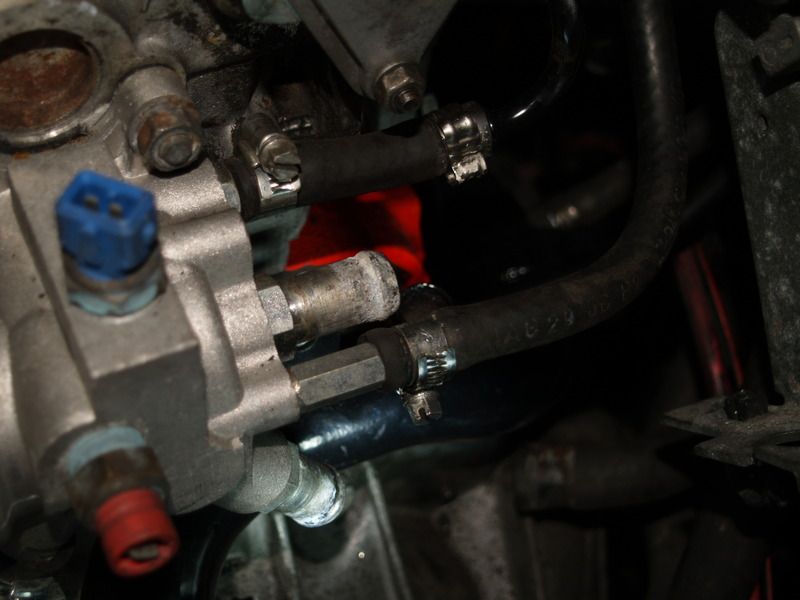

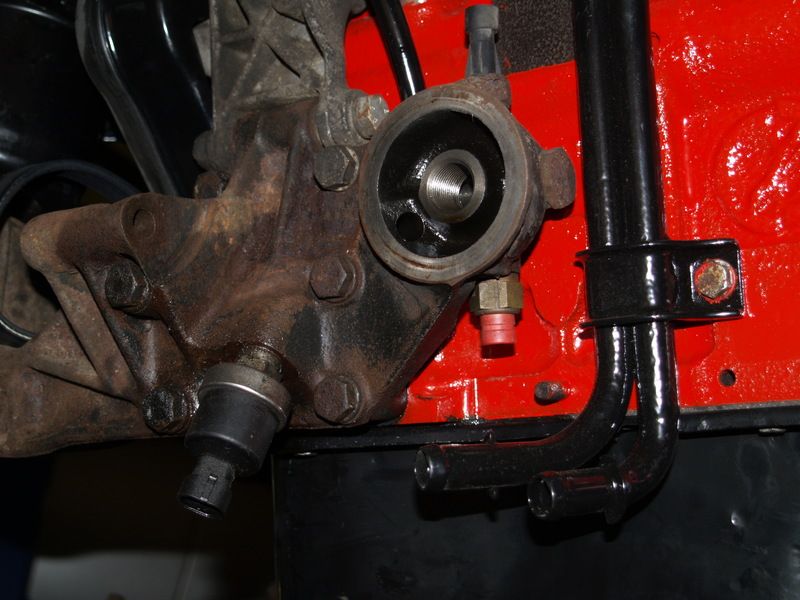

The plumbing around the thermostat is installed:

Then the heat exchanger, alternator, and associated wiring:

Essential earthing points:

The idle control valve (ICV) and wiring

Four into two into one (shame we accidentally powder coated the heat shield... oh well.)

And the clutch slave servo - bolted in on a 16NA. We'll be making a single braided pipe from the master to the slave, given the difficulty of obtaining either new slave hard pipes or pipes to make as new.

The powder coated radiator support bar, the radiator, and we're good to go.

Filled the gearbox, the engine (using a cheap 10W-40 for the first thousand miles or so), and the cooling system.

Time to see if it starts. First, prime the oil; plugs out and the injectors disconnected, and let the engine turn over on the starter for a couple of minutes. This isn't quite fast enough to maintain a pressure indication on the gauge, but ensures that the oil gets to everywhere it needs to. Checking through the filler hole shows the oil is getting pumped around.

Plugs in, connect the HT, and the injectors. Does it start? No.

Investigate... no spark. Some muppet has inadvertently connected the spark coil to the sidelight cluster loom. Oh well.

Now does it start? No.

Hmm, perhaps we got the fuel go and return lines the wrong way round? No... ah, wait, petrol isn't coming out of either pipe and we can't hear the pump.

Turns out some *other* muppet has removed the inertia switch connector. To access this one need only open the door, but the two-post lift won't allow this, and as we haven't put the front wheels on, we can't drop it off. So there is much amusement as we take turns dangling in through the driver's window and try to connect this plug and socket, upside down and legs waving. Eventually we succeed.

The pump priming now works, and makes horrible noises as it blows air through the pressure regulator. After half a dozen primes it runs quietly, so we try and start again.

Woohoo. It runs, and the pressure is right where it should be. Which is nice.